Test Drive

Case Study

Date:

9/12/2015

Category:

Solutions Engineering

Project:

Prototype and Circuit Design

Role:

Solutions Architect, Designer and Engineer

Project Problem

AutoParts.Repair needed a tool to power on and test automotive instrument clusters without a vehicle.

Requirements

- Needs to be versatile for all vehicle manufacturers past and present

- Capable to test many manufacturers for all years

- Capable of testing analog and digital circuits

- Key manufacturers that must be included; BMW, Audi, Mercedes, Bentley, Porsche.

- Create a pattern to mimic a vehicle from start Engine On, To running, to drive at 100 MPH, to ACC, to Engine off

- Check gauges and all indicator lamps

- Check back lighting lamps

Project Solution

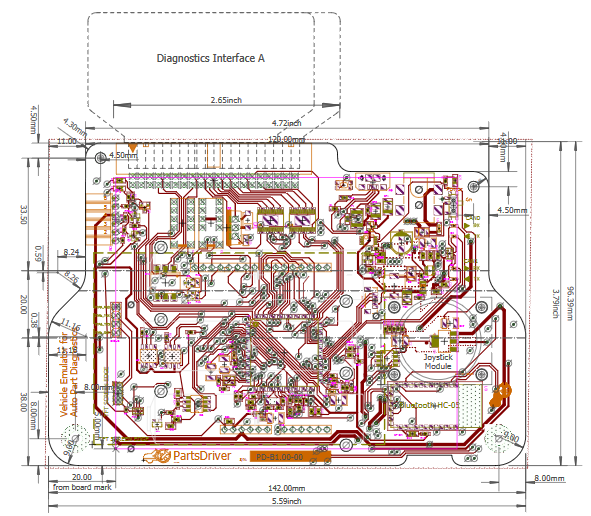

Designed and developed a custom touchscreen prototype for AutoParts.Repair to test and assist with the diagnosis of electronic automotive parts. The device, a 12v ARM micro-controller with touchscreen, emulates a vehicle’s running vitals to drive and test electronic auto parts without the vehicle. CAN Bus, PWM and other vehicle communication technologies and methods were utilized using the solution was built using C++ with VS/Arduino IDE as the core development tools. AutoCAD, Eagle and Mach5 CNC were used for the prototyping of the case and circuit board.

Project Deliverables

Test Drive v1.0

Automotive Parts Driver Prototype

Skill Tags:

ARM, Micro-controller, IoT, MS Code, Arduino, Can-Bus, SPI, MOSI, Circuit Layout , C++, SQL 2008,C , Json, electronics engineering, product development